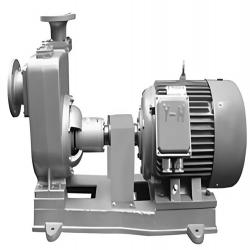

screw pump transfer Naphtha fuel oil

- Model Number: 2W/V

- Brand Name: kenshine-pump

- Place of Origin: Shanghai, China

- Minimum Order Quantity: 1set

- Supply Capacity: 300sets per month/month

- Payment: T/T in advance

- MemberShip: Free Member

- Inquiry Now

2W/V screw pump transfer Naphtha fuel oil Description

Naphtha transfer pump

Twin screw pump is a rotary upright pump, with gears and bearings located externally and not in contact with the conveyed liquid. The pressure, flow rate, temperature, and viscosity of the conveyed liquid have a wide range, such as gasoline, hydrocarbons, seawater, high viscosity liquids such as asphalt, tar, adhesives, molasses, and corrosive media such as acids and alkalis.

Medium viscosity: 1-1500mm2/s

Pump pressure range: 4.0MPa

Flow range: 1-2000m3/h

Temperature range: -15 to 280 degrees Celsius

Pumps can transport media such as lubricating oil, hydraulic oil, cutting oil, cooling oil, wax, tar, light oil, liquefied petroleum gas, crude oil, heavy oil, and asphalt.

Oil and gas

Twin screw pumps are ideal pumps for transporting crude oil, natural gas, water, and solid mixtures. They can be used on land and at sea. The pump can operate dry and transport media containing gas. Its compact design and special thread profile ensure long-distance pipeline transportation.

Application of multiphase crude oil transportation, thermal power plants, and crude oil storage.

ocean

Twin screw pumps can be used on oil tankers for loading and transportation, lubricating the main engine, and transporting tar, asphalt, light and heavy fuel oils, crude oil, and chemicals.

Petrochemical industry, refinery

This pump can transport low viscosity liquids, including media with neutral, alkaline, acidic, or gaseous or abrasive materials

Applied to heavy oil, asphalt, tar, heavy fuels, naphtha, and chemical products

chemical industry

Whether low viscosity or high viscosity, it can transport various liquids with corrosiveness and solid particles,

Pumps are used for transporting polymers, coatings, slurries, liquid sulfur, or chemicals.

1、 Fluid characteristics of mixed naphtha

Blended naphtha refers to a mixture of naphtha and a certain proportion of light hydrocarbons. Due to the addition of light hydrocarbons, the fluid characteristics of mixed naphtha are more complex than those of pure naphtha. Specifically, blended naphtha has the characteristics of high viscosity and high specific gravity, and the viscosity decreases with increasing temperature, which poses certain difficulties in pump selection.

2、 Characteristics of screw pumps and centrifugal pumps

1. Screw pump

Screw pump, also known as rotary thruster, works by pushing liquid into the pipeline through the rotation of the screw. The main characteristics of screw pumps are strong adsorption capacity and pressure stability, and the ability to transport high viscosity liquids.

2. Centrifugal pump

A centrifugal pump refers to a type of pump that uses centrifugal force to push liquid into a centrifugal casing, and then discharges it through an outlet pipe. The main characteristics of centrifugal pumps are high flow rate and stable pressure, but they are prone to blockage when transporting high viscosity liquids.

3、 Choose the appropriate pump

Due to the fluid characteristics of blended naphtha itself, when selecting a pump, it is necessary to consider both flow rate and pressure stability, as well as adaptability to high viscosity liquids.

In this case, screw pumps are more suitable for transporting mixed naphtha. The adsorption capacity and pressure stability of screw pumps can effectively solve the problem of transporting high viscosity liquids. In addition, the repair and maintenance costs of screw pumps are relatively low, and their reliability is high.

Although centrifugal pumps have advantages in terms of flow rate, they are prone to blockage and overload when transporting high viscosity mixed naphtha, which can cause unnecessary problems during operation

| flow rate | 1-2000m3/h |

|---|---|

| pressure | 4MPA |

| pump material | Cast iron, stainless steel, carbon steel |

| oil pump | fuel pump |

| screw pump | transfer pump |

| feeding pump | booster pump |

| heavy oil pump | twin screw pump |

| kenshine-pump | china pump |

Retaled category: Screw Pump

Hot search: screw pump, oil pump, fuel pump, transfer pump, booster pump, feeding pump